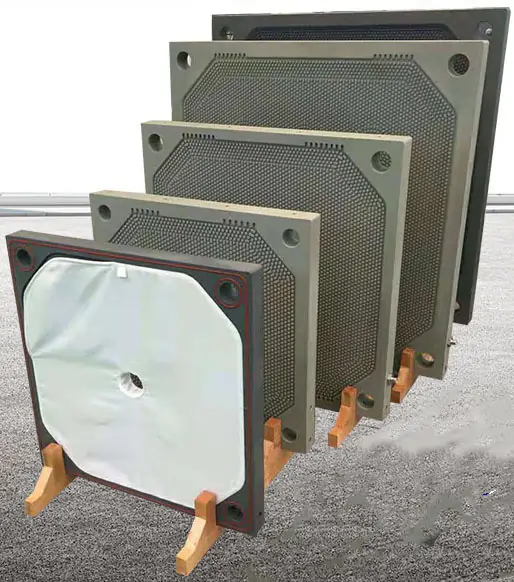

Polypropylene Filter Press Plates – High-Efficiency Industrial Filtration Solutions

Our polypropylene filter press plates are engineered for efficient solid-liquid separation across demanding industrial applications. With outstanding chemical resistance and long-term stability, they are ideal for chemical, mining, metallurgy, and wastewater treatment industries.

Key Features:

- Material: 100% pure polypropylene (PP), corrosion-resistant and non-toxic

- Available Sizes: From 400 mm to 2000 mm (customizable upon request)

- Pressure Range: Up to 1.6 MPa (standard), high-pressure options available

- Plate Structures: Chamber, diaphragm (membrane), and plate-frame

- Temperature Resistance: Up to 90°C with standard PP; higher temperature options available

- Surface Treatment: Polished finish to reduce cake adhesion and ease discharge

Industry Applications:

- Chemical Industry: Acid, alkali, solvent and fine chemical filtration

- Mining & Metallurgy: Slurry dewatering and tailings treatment

- Wastewater Treatment: Municipal and industrial sludge dewatering

- Food & Beverage: Juice clarification and edible oil filtration

- Pharmaceuticals: Active ingredient and biotech product separation

OEM & Custom Services

- We offer OEM solutions including branding, mold customization, and design optimization based on your equipment and process needs.

- Options include high-temperature resistance, advanced cake discharge designs, and custom gasket configurations.

Why Choose Our Filter Press Plates?

- ✔ Factory direct supply with rigorous quality control

- ✔ 15+ years of manufacturing experience

- ✔ ISO and CE certified for international standards

- ✔ Exported to over 40 countries worldwide

- ✔ Engineering support and rapid delivery