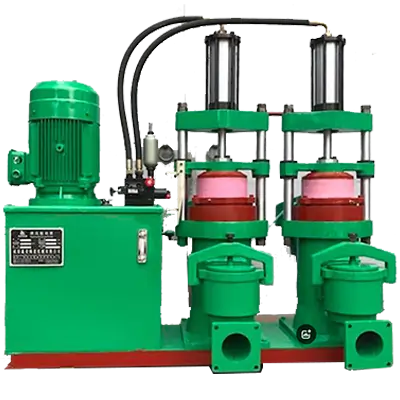

Ceramic Plunger Pump for Filter Press Feeding

The Senjie Ceramic Plunger Pump is purpose-built for chamber filter presses, membrane filter presses, and other industrial filtration systems. Featuring a wear-resistant ceramic plunger design, this pump delivers stable, high-pressure feeding for efficient solid-liquid separation, sludge dewatering, and wastewater treatment. As an essential filter press accessory, it provides outstanding performance in harsh operating conditions, especially with abrasive or corrosive slurries common in mining, ceramics, chemical, and environmental industries.

Main Features of Ceramic Plunger Pump

- Specifically engineered as a ceramic plunger pump for filter press feeding, compatible with both chamber and membrane filter press systems

- Ceramic plunger construction delivers superior resistance to abrasion and corrosion, making it ideal for aggressive and high-solids slurries

- High pressure and stable flow, ensuring optimal solid-liquid separation and maximum filter press efficiency

- Heavy-duty cast iron housing with ceramic plunger for long service life and reliable operation in tough environments

- Simple structure, easy maintenance, and low operating costs

- Widely used in mining, ceramics, chemical, food, and wastewater treatment applications

Typical Technical Parameters

- Flow Rate: 1 – 60 m³/h (customizable to filter press system requirements)

- Max Pressure: 0.6 – 2.5 MPa (suitable for chamber and membrane filter press feeding)

- Material: Cast iron body with ceramic plunger, or optional stainless steel for high-corrosion applications

- Motor Power: 3 – 55 kW, suitable for different filter press pump setups

- Inlet/Outlet Size: DN50 – DN150, compatible with standard filter press piping

- Perfect for solid-liquid separation, ceramic slurry transfer, sludge dewatering, and industrial wastewater treatment

| Model | Rated Flow (m³/h) | Pressure Range (MPa) | Strokes (per min) | Stroke (mm) | Motor Power (kW) | Dimensions (mm) | Suction/Discharge Pipe Dia (mm) | Suitable Filter Press Volume (m³) |

|---|---|---|---|---|---|---|---|---|

| YB75-Single | 0.7 | 0–2.5 | 21 | 220 | 3 | 870×740×1450 | Φ45 (45) | 2–10 |

| YB85-Single | 1.5 | 0–2.5 | 15 | 220 | 3 | 1000×900×1400 | Φ48 (48) | 2–10 |

| YB85-Double | 3 | 0–2.5 | 15 | 220 | 4 | 1300×1050×1400 | Φ48 (48) | 5–15 |

| YB110-Single | 2.3 | 0–2.5 | 16 | 250 | 4 | 1000×1050×1560 | Φ50 (50) | 5–15 |

| YB110-Double | 4.5 | 0–2.5 | 24 | 250 | 4 (5) | 1100×1250×1560 | Φ50 (50) | 10–30 |

| YB140-Single | 5 | 0–2.5 | 23 | 250 | 7.5 | 1400×1100×1650 | Φ78 (60) | 10–30 |

| YB140-Double | 10 | 0–2.5 | 23 | 250 | 7.5 | 1700×1250×1700 | Φ78 (60) | 30–80 |

| YB140-Double | 12 | 0–2.5 | 26 | 250 | 11 | 1700×1250×1700 | Φ78 (60) | 30–80 |

| YB200-Double | 19 | 0–2.5 | 22 | 250 | 18.5 | 1900×1400×1900 | Φ108 (108) | 80–200 |

| YB250-Double | 30 | 0–2.0 | 18 | 250 | 22 | 2400×1300×1900 | Φ108 (108) | 80–200 |

| YB300-Double | 45 | 0–2.0 | 15 | 250 | 30 | 1950×1900×2000 | Φ159 (133) | 200–300 |

| YB300-Extended | 60 | 0–2.0 | 13 | 350 | 37 | 1950×1900×2300 | Φ159 (133) | 200–300 |

| YB350-Double | 80 | 0–2.0 | 12 | 430 | 55 | 2300×2100×2600 | Φ159 (159) | 200–300 |